In a quiet pocket of Galveston County, Dickinson High School shines with their advancement of future craft professionals through the school’s Career and Technical Education (CTE) program. I recently got to speak with four high school seniors about their experiences in the welding program and their plans for their futures.

In a quiet pocket of Galveston County, Dickinson High School shines with their advancement of future craft professionals through the school’s Career and Technical Education (CTE) program. I recently got to speak with four high school seniors about their experiences in the welding program and their plans for their futures.

Bob Harris is a high school senior who has been a part of the welding program at Dickinson High School (DHS) for three years. He was encouraged to enter the program by his sister who had friends in the program who said great things about it. I asked him what he has found most interesting or challenging about the program. Bob said it was the projects which they were assigned. He said “The projects were very interesting – they were fun just to learn how to weld on different types of metal at different amps, and to get certifications.” After graduation he hopes to work for a company like Performance Construction,  working on pipelines. He would also like to one day be the owner of a company that makes customized grills, metal artwork, and other specialized metal project requests. I asked what types of projects he has worked on through the DHS program. He said that he had worked on a barbeque pit, a pipe rack, and a go-cart. I did not know what a “pipe rack” was, so I asked to see one. It is basically a holder for extra pieces of cut-off pipe which would be in the way and also a safety hazard if they were just set on the floor. I asked Bob if he would recommend welding as a career to other young people, he said “Yes!”

working on pipelines. He would also like to one day be the owner of a company that makes customized grills, metal artwork, and other specialized metal project requests. I asked what types of projects he has worked on through the DHS program. He said that he had worked on a barbeque pit, a pipe rack, and a go-cart. I did not know what a “pipe rack” was, so I asked to see one. It is basically a holder for extra pieces of cut-off pipe which would be in the way and also a safety hazard if they were just set on the floor. I asked Bob if he would recommend welding as a career to other young people, he said “Yes!”

Javier Barreto has been in the welding program at DHS for four years. He hopes to start a career working in the petroleum industries, using the skills he has gained in the program to move straight out of high school and begin working for a company. I asked Javier how he choose to study welding. He said he looked at the course selection and thought that manufacturing sounded “fun” because “you are making something or you are taking it apart!” When I asked about his career goals, Javier told me that he hopes to one day become a welding inspector and perhaps even work his way up to become CEO of his own company.

Javier was then joined by Norman Narcisse, who has participated in the welding program for the last two years. Norman told me that he knew a couple of friends who were in the program and really liked it, so he decided to give it a try. I asked him what he had enjoyed most out of the subjects and skills he had studied. He gave a very technical answer when he replied “I have been learning about what amperage and rods to use on certain welds. There’s different types of welding like overhead, vertical, horizontal – there’s all different stuff. It’s really cool.” Javier added “You’re also doing MIG, TIG, stick, and plasma cutting as well.” Norman: “A little bit of everything, yeah.”

After graduation, Norman plans to attend a college where he can study pipe welding and then find a starting job with a company that will help him grow his skills. Javier summed up his appreciation of the craft: “You know learning new things in welding is fascinating. You learn [about] different types of people you get to work with, and you try to cooperate. It is a group effort. You’re not just ‘you do your job’ – you’re working with a group. You are part of a team. You work with each other no matter what.”

“You know learning new things in welding is fascinating. You learn [about] different types of people you get to work with, and you try to cooperate. It is a group effort. You’re not just ‘you do your job’ – you’re working with a group. You are part of a team. You work with each other no matter what.”

Last, I visited with Stori Sneller, a high school senior who has been in the welding program for three years.

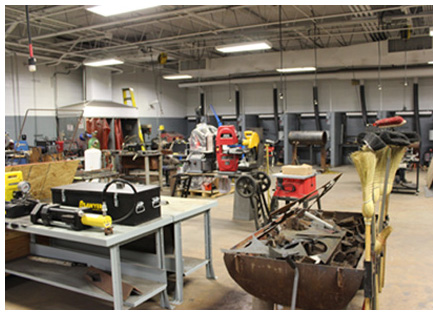

She told me that her uncle is in welding, doing small jobs “here and there.” She knows that after graduation she could work for him or for another contact she has in a similar business, but she is hoping to work for a larger company – perhaps something her welding instructor could set up. Always willing to help where needed, she sometimes helps her step-dad, an airplane mechanic, work on “whatever projects he needs.” When her instructor at the high school had to miss some work, Stori stepped in and took over leadership of the class. They struggled with the assignment to build a pipe rack (see photo) from a blueprint, and the first version built was incorrect. To add to their difficulties, the shop press was broken for a while, which delayed students from completing the skills needed for their certifications.

When her instructor at the high school had to miss some work, Stori stepped in and took over leadership of the class. They struggled with the assignment to build a pipe rack (see photo) from a blueprint, and the first version built was incorrect. To add to their difficulties, the shop press was broken for a while, which delayed students from completing the skills needed for their certifications.

I asked Stori what she would say to someone like herself who might be considering welding as a career. She replied: “I would say ‘Best wishes to you.’ I hope you have your safety glasses and your helmet on because you will be blinded if you don’t have the right [equipment] – you will get burned and it is not fun or easy to go through that. But putting things together, forming an actual project, and helping with other people – that’s a fun thing to do.”

I said it must be great at the end of a project to look at it and say “I made that.” Stori nodded and smiled as she agreed:

“It’s actually a really amazing feeling to say that. ‘I did make that.’ And I didn’t do it just myself, I actually made it with other people. We worked together as a team.”

You can watch more of my interviews with these four students in the 4-minute video below, and look for my interviews with two of their welding instructors in an upcoming post.

High School CTE Program Jump-Starting Careers [VIDEO]

by Elizabeth McPherson | May 12, 2016