Craft Focus: “Once I Became a Welder, Everything Changed” [VIDEO] [1]

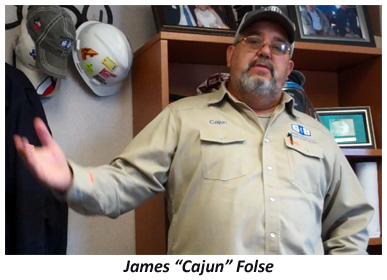

Last fall I had the opportunity to visit one of the Lone Star NGL Fractionator Projects in Mont Belvieu, Texas which S & B Engineers and Constructors [10] was building. At the jobsite, I met James “Cajun” Folse, the Welding Program Manager, to learn about the in-house welding program at S & B.

Last fall I had the opportunity to visit one of the Lone Star NGL Fractionator Projects in Mont Belvieu, Texas which S & B Engineers and Constructors [10] was building. At the jobsite, I met James “Cajun” Folse, the Welding Program Manager, to learn about the in-house welding program at S & B.

The day I visited the jobsite, three NGL fractionation units in the immediate vicinity were already operational (Frac I, Frac II, and Mariner South); Frac III and Frac IV were under construction; and construction was scheduled to begin soon on Frac V – making a total of six fractionator projects that S & B constructed and would construct for Lone Star NGL LLC.

Folse explained that S & B developed their onsite welding school to offer to employees as an after-hours self-enrichment opportunity. Students go through an extensive 8-week classroom portion before then learning “hands-on” in the welding labs. To become certified, they then have to pass inspection by the S & B quality control department. Graduates of the Combination Welder course receive a certificate and a hardhat with the S & B Welding Program logo and their own names. The original welding classroom was built inside of a trailer in which six students could train at a time, usually twice a week after work. Additional training was sometimes offered during lunch breaks. Due to the success and popularity of the program, S & B is setting up a larger training facility in which up to 48 students can train at once. Folse said that 32 students were currently enrolled and 80 others were waiting to begin the program.

The original welding classroom was built inside of a trailer in which six students could train at a time, usually twice a week after work. Additional training was sometimes offered during lunch breaks. Due to the success and popularity of the program, S & B is setting up a larger training facility in which up to 48 students can train at once. Folse said that 32 students were currently enrolled and 80 others were waiting to begin the program.

Folse introduced me to Luis Valdovinos, a Welding Foreman and Instructor at

S & B who started working for the company three years ago as a pipefitter helper. Before I interviewed Valdovinos about his career with S & B, we stopped by the field office of Construction Manager Ben Sims. We talked about some of the success stories the Welding Program has produced.

Sims mentioned Michael Guzman who began with the company as a utility laborer and has now passed his structural test and is a qualified Combination Welder. He also mentioned Shawn Montalbano who is “a kid who chose construction over going to college, and one day he will get there.” Sims said, “There are a number of guys who are out there in the program who have done just that.” Another name mentioned was Jonathan Pesina. “That kid is a star, too. He teaches a class, he has a beautiful family, he is a nice young man, and now he has a good career. These guys, if they choose to [work hard], they will never miss a check. There is always a demand in Houston, Texas for guys with this talent.” I asked where people get welding training if they are not in the S & B Welding Program. Folse and Sims mentioned several colleges which offer welding programs – many of whom S & B is also involved with. The same skills are taught in each of the college programs as are taught at S & B. Graduates of each programs receive certificates which qualify them to work anywhere – that is after they pass a weld test. When a welder is hired, no matter where the worker received training or who his or her previous employer was, he or she must pass a weld test. Each must demonstrate his or her talents for the new employer.

I asked where people get welding training if they are not in the S & B Welding Program. Folse and Sims mentioned several colleges which offer welding programs – many of whom S & B is also involved with. The same skills are taught in each of the college programs as are taught at S & B. Graduates of each programs receive certificates which qualify them to work anywhere – that is after they pass a weld test. When a welder is hired, no matter where the worker received training or who his or her previous employer was, he or she must pass a weld test. Each must demonstrate his or her talents for the new employer.

S & B made the decision to invest in their own welding program when they first began work on the Lone Star projects, even though at first there was no money in the budget for the program. Now for Frac IV and future projects, there is money in the budget for the welding program because as Sims explained:

“For the last four years we have been at Lone Star doing this on our own nickel and reinvesting in our own guys, because – 1) I believe and 2) others believe – that this is the right thing to do. And I haven’t been criticized or slapped on the hand for spending the money. They have actually applauded us and recognized us for good behavior and trying to do the right thing.”

Valdovinos added that if it weren’t for the S & B Welding Program opportunity, he would not be where he was today. Sims agreed and said that there were a number of guys who would say the exact same thing.

After our visit with Sims, Folse and Valdovinos drove me next to the site of Frac III (“Frac Three”) so that I could interview Valdovinos with the active construction site in the background. Luis Valdovinos began his career in construction working scaffolding. While working on jobsites he observed the pipefitters’ work and became interested in learning that skill. It was as a pipefitter that he was first hired at S & B as a pipefitter helper. While working as a pipefitter, he observed the welders and dreamed about becoming a welder himself. Valdovinos, who has an 8-year-old son and a baby daughter, thought that he would never have the chance to get the necessary training to become a welder because of the time commitment of driving to a training facility after working a full day before finally driving home to his family. When he found out that S & B was offering welding training after hours on the same site where he was working, he did all he could do to be accepted to the program. In his words:

Luis Valdovinos began his career in construction working scaffolding. While working on jobsites he observed the pipefitters’ work and became interested in learning that skill. It was as a pipefitter that he was first hired at S & B as a pipefitter helper. While working as a pipefitter, he observed the welders and dreamed about becoming a welder himself. Valdovinos, who has an 8-year-old son and a baby daughter, thought that he would never have the chance to get the necessary training to become a welder because of the time commitment of driving to a training facility after working a full day before finally driving home to his family. When he found out that S & B was offering welding training after hours on the same site where he was working, he did all he could do to be accepted to the program. In his words:

“Once I started going to school, I liked it. I found out that this was something I could see myself doing for the rest of my life.”

Valdovinos completed his structural course certification, and then went on to complete the combination course. From there he advanced to become a welding foreman and also an instructor for the welding program. He told me “[S & B] offered to make me an instructor, and of course I wanted to give back something that somebody else taught me. I wanted to continue helping people out.”

I asked Valdovinos what he liked best about being an instructor and sharing his trade with others. He replied:

“I like it because I know that person’s life – and not just his but his entire family’s – is going to be better. Just like it happened with my family: once I became a welder, everything changed.”

You can watch some of Sims’ and Valdovinos’ remarks in the following 5-minute video.